The process of

SLA 3D printer combined with FRP mainly includes the following steps:

1. Design and preparation stage

Design model: First, use CAD (computer-aided design) software to design the required three-dimensional digital model. This model is the basis for subsequent 3D printing.

Slicing: Import the designed 3D model into the slicing software to generate a slicing file. During the slicing process, parameters such as printing layer height and filling density can be adjusted to optimize the printing effect.

Prepare materials: Load the photosensitive resin into the material tank of the SLA 3D printer, and prepare the FRP materials required for subsequent processing, such as fiberglass cloth, epoxy resin, etc.

2. SLA 3D printing stage

Print the bottom layer: The SLA 3D printer will first print a bottom layer to fix the position of the model and ensure the printing quality.

Print layer by layer: According to the instructions of the slicing file, the SLA 3D printer will solidify the photosensitive resin layer by layer and print the model layer by layer from bottom to top. The laser or light beam will irradiate the photosensitive resin to solidify it to form each layer of the model.

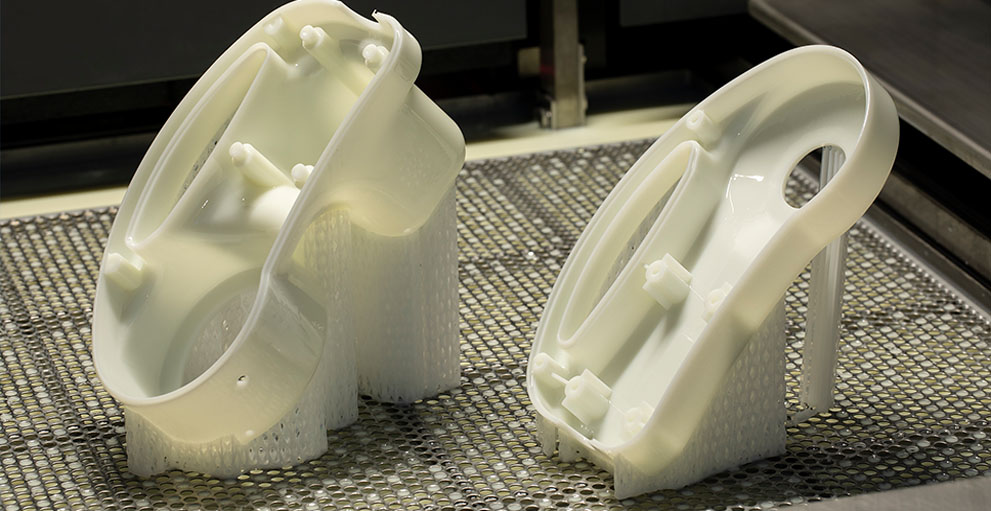

Finish printing: When all layers of the model are printed, the printer will stop automatically. At this time, the printed object needs to be removed from the light curing tank.

III. Subsequent processing and fiberglass bonding stage

Remove support structure: After removing the printed object, the support structure added during the printing process needs to be removed for subsequent processing.

Surface treatment: Perform necessary surface treatment on the printed model, such as polishing, cleaning, etc., to improve its surface finish and bonding ability with fiberglass materials.

Apply fiberglass material: After applying the release agent on the surface of the model, place the prefabricated fiberglass cloth outside or inside the model (depending on the specific needs), and then evenly apply epoxy resin with a brush or spray gun to penetrate the fiber cloth. As needed, the coating and spreading process can be repeated until the required thickness and strength are achieved.

Curing treatment: Put the model coated with fiberglass material into a high-temperature oven for curing treatment, so that the epoxy resin is fully cured and tightly bonded with the fiberglass cloth. The curing time depends on the material used and the size of the model.

Demolding and post-processing: After curing treatment, the model is removed from the mold and demolded. Finally, necessary post-processing operations such as grinding and finishing are carried out to achieve the final required quality and appearance.

IV. Finished product application

After the above process, the products made by SLA 3D printer combined with FRP technology have the advantages of high strength, high corrosion resistance, high temperature resistance, etc., and can be widely used in sculpture, architectural decoration, automobile manufacturing, aerospace and other fields.

It should be noted that the process flow of SLA 3D printer combined with FRP may vary depending on the specific application scenario and material. In actual operation, it should be adjusted and optimized according to the specific situation.

The application of SLA 3D printer combined with FRP shows its unique advantages in many aspects. The following is a detailed analysis of this combination:

V. Advantages

Improve production efficiency:

SLA 3D printing technology can significantly improve the production efficiency of FRP products. By directly printing out complex models, it reduces the tedious steps of mold making, resin coating, curing, etc. in traditional processes, thereby shortening the production cycle.

Realize complex design:

SLA 3D printing technology has a high degree of design flexibility and can easily realize the printing of models of various complex shapes and structures. This makes the design of FRP products no longer limited by the limitations of traditional crafts, providing artists and designers with a broader creative space.

Save time and cost:

Compared with traditional crafts, SLA 3D printing combined with FRP production can greatly save time and cost. Fast printing and simplified process flow reduce labor costs, while reducing material waste and improving overall economic benefits.

High product quality:

The models printed by SLA 3D printing technology have high surface finish and clear details, and can be used after simple post-processing. Compared with traditional processes, the steps of manual finishing and polishing are reduced, which improves the overall quality of the product.

Superior comprehensive performance:

FRP itself has the advantages of light weight, high strength, corrosion resistance, excellent electrical properties, and stable thermal properties. After combining with SLA 3D printing technology, its performance advantages can be further exerted to produce FRP products with superior performance, beautiful appearance and durability.

In summary, the application of SLA 3D printer combined with FRP has significant advantages in improving production efficiency, realizing complex design, saving time and cost. In the actual application of sculpture or FRP industry, it is necessary to carry out process production according to specific needs and conditions.