What are the advantages of SLA 3D printers in rapid prototyping for product development?

SLA (Stereolithography) 3D printers have significant advantages in rapid prototyping for product development. These advantages are mainly reflected in the following aspects:

Advantage

High precision and surface quality:

SLA 3D printers use laser beams to precisely scan liquid photosensitive resin to solidify it layer by layer, enabling high-precision and high-surface-quality printing. This technology can produce parts with tolerances typically less than 0.05 mm and provides the smoothest surface finish of any additive manufacturing process. (Source: Sohu.com)

Wide range of material options:

SLA technology can use various types of photosensitive resins, including white, translucent, fully transparent, high toughness, etc., to meet different performance requirements. In addition, there are also special materials for special requirements, such as heat-resistant resin, fully transparent resin, etc., which provide more possibilities for product development. (Source: Sohu.com)

Fast processing and short production cycles:

SLA 3D printers can produce prototypes directly from CAD digital models without the need for cutting tools and molds, greatly shortening the product development cycle. This is especially important for product development processes that require rapid iteration and validation of design concepts. (Source: Sohu.com)

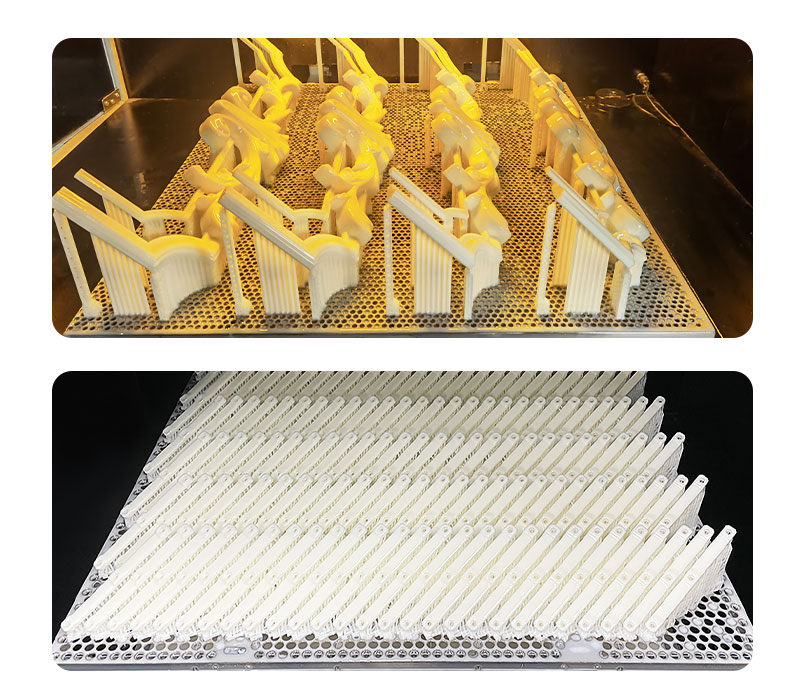

Adaptability to complex geometries:

SLA technology is capable of manufacturing prototypes with complex geometries, which is a huge advantage for parts that are difficult to form using traditional processes. It enables product developers to explore more innovative design solutions. (Source: Harbin Institute of Technology 3D)

Functional testing:

In some cases, SLA 3D printed prototypes can also be used for functional testing, helping product developers verify the feasibility and performance of the design before actual production.

Characteristics compared with traditional craftsmanship

Greater precision and surface quality:

Compared with traditional processes, SLA 3D printers can provide higher precision and smoother surface quality, making the prototype closer to the appearance and performance of the final product.

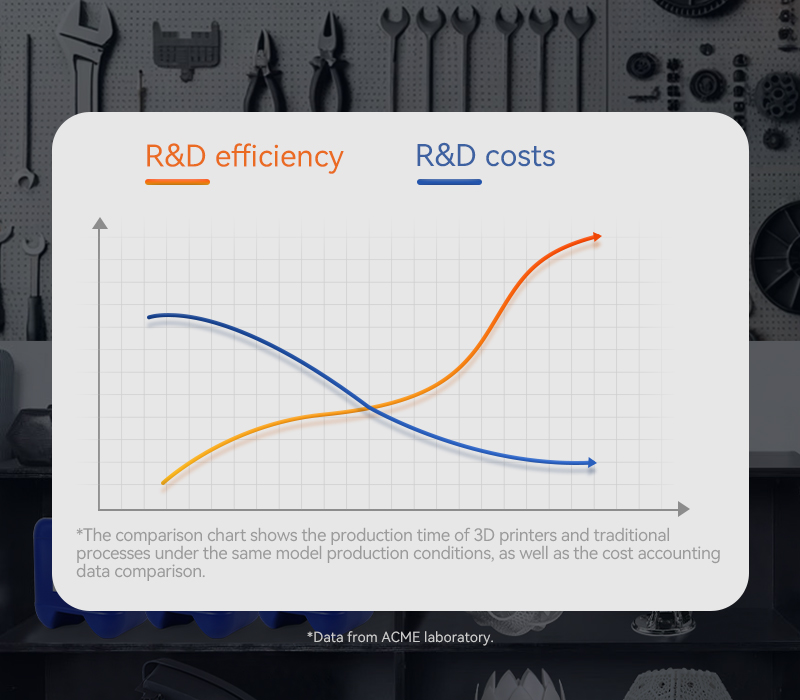

Shorter production cycle:

SLA 3D printing technology eliminates the steps of mold making and cutting in traditional processes, greatly shortening the production cycle and improving product development efficiency.

Lower cost:

For small batch or customized product development, SLA 3D printing technology can reduce costs such as mold making and cutting processing, making product development more cost-effective.

Greater design flexibility:

SLA 3D printing technology can produce prototypes of complex geometric shapes, providing product developers with greater design freedom and helping to promote innovation in product design.

To sum up, SLA 3D printers have the advantages of high precision, high surface quality, wide range of material selection, rapid processing and short production cycle in terms of rapid prototyping for product development. Compared with traditional processes, SLA 3D printers have higher design flexibility and Lower costs. These advantages make SLA 3D printing technology widely used in the field of product development.