The advantages of industrial 3D printers in the foundry industry are mainly reflected in the following aspects:

Production efficiency: The traditional casting production process needs to make molds, and perform multiple melting, casting, cooling and other steps. The production cycle is long. However, industrial-grade 3D printers can quickly produce models and print them, which greatly improves production efficiency.

Precision control: In the casting production process, the precision of mold processing will directly affect the quality of castings, while traditional mold making is difficult to achieve high-precision machining, while industrial-grade 3D printers can accurately control various parameters in the printing process, thereby ensuring the quality of the printed parts. accuracy.

Plasticity: Industrial-grade 3D printers can use a variety of materials for printing, which can meet the different needs of the foundry industry. For example, using ceramic materials to print molds can improve the high-temperature resistance of the mold.

Optimized design: Free design can be realized by using industrial-grade 3D printers, and the model can be modified and optimized arbitrarily to improve the quality and performance of castings.

Fine processing: Using industrial-grade 3D printers can produce very fine models and complex-shaped castings to meet the foundry industry's demand for high-precision, complex-shaped castings.

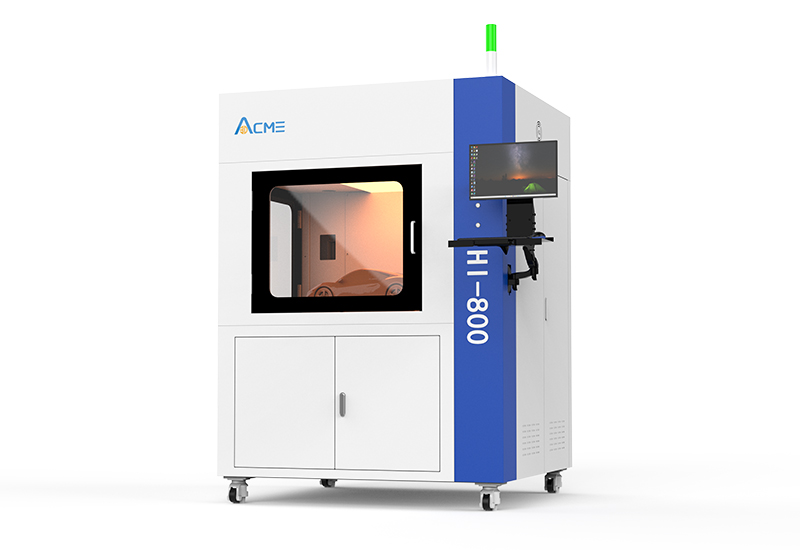

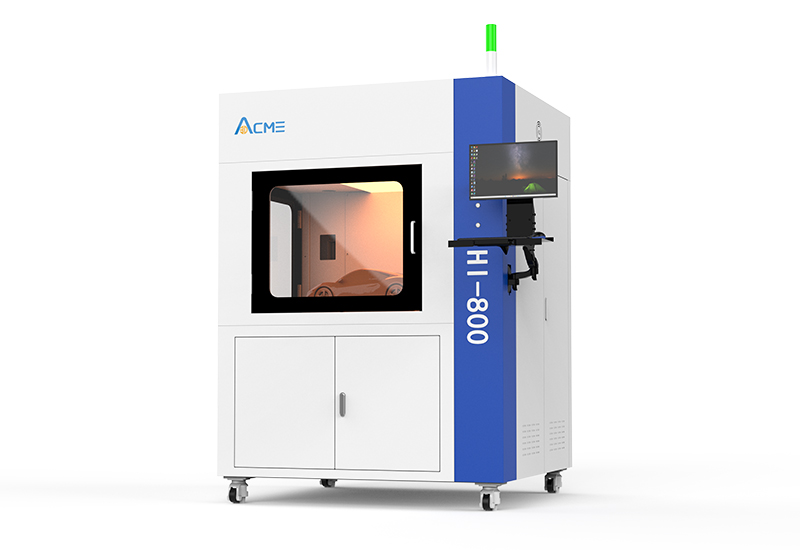

Acme industrial-grade 3D printers have certain application advantages in the foundry industry. The foundry industry usually needs to manufacture parts with high precision, complex shapes and unique structures. However, traditional casting methods are limited by mold manufacturing and cannot fully meet these needs. However, 3D printing technology can avoid the manufacture and design of molds by directly and rapidly producing three-dimensional entities, thereby improving production efficiency and production cycle.

Acme industrial-grade 3D printer adopts advanced molding technology and precision control system, which can manufacture parts with high precision and complex shapes, and has a wide variety of materials, which can be applied to different types of casting processes. In addition, Acme can also provide customized solutions, and formulate suitable printing schemes and material selections according to customer needs to meet the special needs of the foundry industry.

Overall, Acme industrial-grade 3D printers have certain market competitiveness and application potential in the foundry industry, and can provide more efficient, flexible and accurate production solutions for foundry companies.