SLA (Stereolithography) 3D printers are mainly suitable for industries that require high precision and high surface quality, such as medical equipment, jewelry, glasses, industrial design, automobiles and other fields. SLA 3d printers can print very detailed models with very smooth surface quality, so they are very suitable for making small, high-precision parts, models and molds. In the field of medical equipment, SLA 3d printers can be used to make models of human organs, teeth, etc.; in the field of jewelry, SLA 3d printers can be used to make jewelry models with high precision and high surface quality. In addition,

SLA 3d printers can also be used in rapid prototyping, prototyping, and parts manufacturing with complex structures.

SLA 3d printers have a wide range of applications in medical devices, jewelry, eyewear, industrial design, and automotive. The following introduces its advantages in each field:

Medical device field: SLA 3d printers can manufacture high-precision, high-quality medical device models, such as surgical simulators, human anatomy models, etc. Before the operation, doctors can conduct surgical drills through the model to reduce the risk of surgery. In addition, SLA 3d printers can also manufacture orthotics, prosthetics and other medical devices.

Jewelry field: SLA 3d printers can manufacture high-precision and high-complexity jewelry models, such as rings, earrings, necklaces, etc. Compared with traditional jewelry manufacturing methods, SLA 3d printers can reduce manufacturing costs and time, and can create more exquisite jewelry.

Glasses field: SLA 3d printers can manufacture high-precision, high-quality glasses models, such as glasses frames, lenses, etc. With SLA 3D printers, eyewear manufacturers can quickly manufacture eyewear products that meet customer needs, improving manufacturing efficiency and customer satisfaction.

Industrial design field: SLA 3d printers can manufacture high-precision, high-quality industrial design models, such as auto parts, mechanical parts, etc. With SLA 3d printers, designers can quickly manufacture multiple different design schemes, and can perform physical display and testing, reducing design risks and costs.

Automotive field: SLA 3d printers can manufacture high-precision, high-strength auto parts models, such as engine parts, chassis parts, etc. With SLA 3d printers, car manufacturers can quickly manufacture parts that meet the requirements, and can conduct physical testing and verification, reducing design risks and costs.

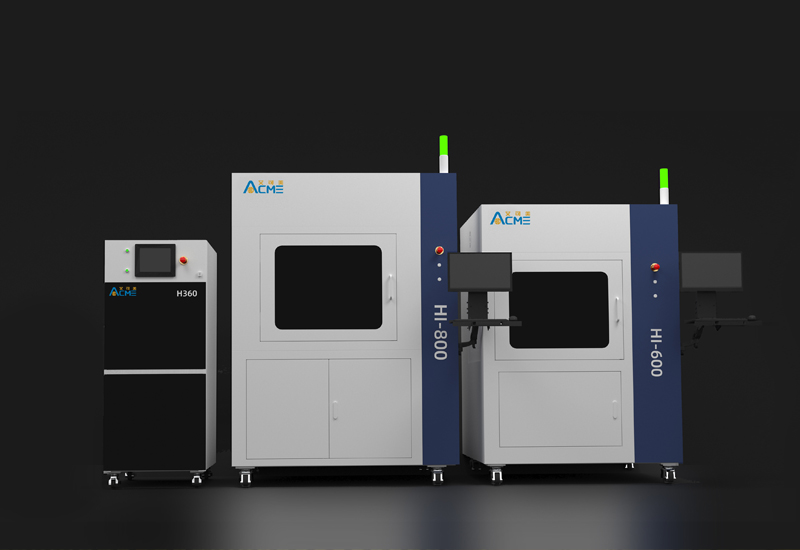

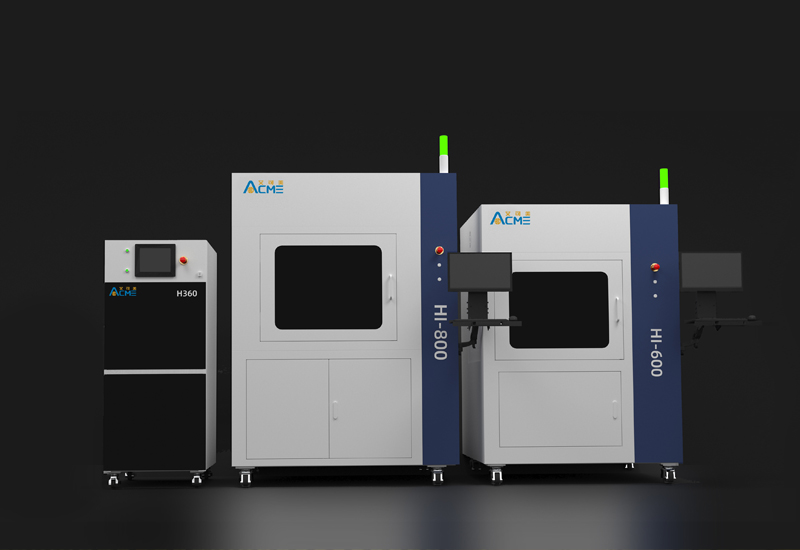

Acme has a variety of products in the field of

SLA 3d printers, such as H360, HI600, HI800 and other models, which are widely used in medical equipment, jewelry, automobiles, industrial design and other fields. Its SLA 3d printer has advantages in precision, speed, stability, etc., and can meet the needs of different fields. In addition, Acme also provides comprehensive after-sales service, including training, maintenance, technical support, etc., which has been recognized by users.