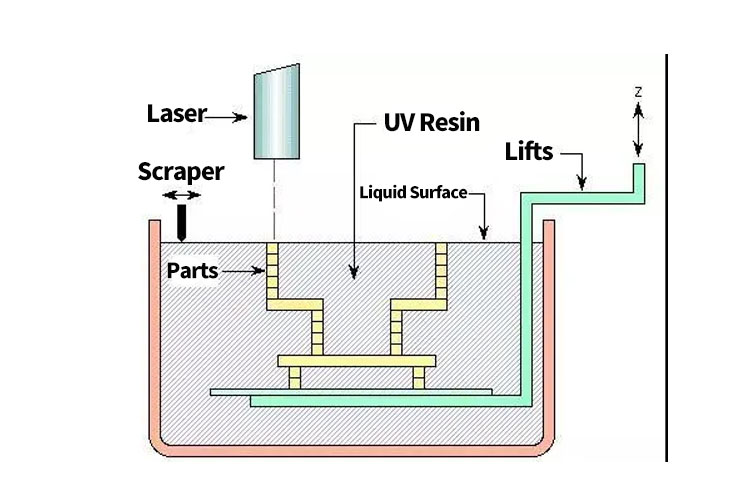

SLA is the abbreviation of "Stereo lithography Appearance", that is, stereolithography. Use a laser with a specific wavelength and intensity to focus on the surface of the light-curing material, so that it is sequentially solidified from point to line, from line to surface, and completes a layer of drawing work, and then the lifting table moves in the vertical direction for a layer height, and then solidifies Another level. In this way, layers are superimposed to form a three-dimensional entity.

The SLA stereolithography method was first proposed in different places from the late 1970s to the early 1980s by Alan jHebert of 3M in the United States, Hideo Kodama in Japan, Charles W.Hull in UVP in the United States, and Yoji Marutani in Japan. The concept of RP is a new idea of using continuous layer solidification to generate three-dimensional solids. In 1986, the SLA-1 produced by Charles W. Hull of UVP Company was patented.

1. SLA process characteristics

Stereolithography (SLA) mainly uses photosensitive resins as raw materials, and utilizes the property that liquid photosensitive resins can be cured rapidly under the irradiation of ultraviolet laser beams. The photosensitive resin is generally in a liquid state, and it immediately causes a polymerization reaction under the irradiation of a certain wavelength of ultraviolet light (250 nm to 400 nm), and completes the curing. The printing consumables that SLA technology can currently use are photosensitive resins, which are mainly used to manufacture a variety of molds, models, etc.; it is also possible to add other components to the raw materials to replace the wax molds in investment precision casting with SLA prototypes.

Before printing, the resin tank is filled with liquid photosensitive resin, and the liftable workbench is at the height of a cross-sectional layer thickness under the liquid surface. The focused laser beam scans along the liquid surface under the control of the computer, and the scanned area is cured, thereby Obtain a thin layer of resin in this cross-section; the lifting table descends a distance of layer thickness, the liquid resin is exposed to light again, scans and solidifies again, and repeats this until the entire product is formed; the lifting table rises from the surface of the liquid resin, takes out the workpiece, and carries out Relevant post-processing, through strong light, electroplating, painting or coloring, etc. to obtain the desired final product.

2. SLA process printing equipment

H360 light-curing rapid prototyping system is mainly composed of laser, galvanometer scanning system, host forming room, scraper mechanism, control system, resin cylinder, computer and software. The ultraviolet light of a specific wavelength and intensity is focused on the surface of the photocurable material, so that it is solidified sequentially from point to line and from line to surface, so as to complete the drawing of a layer section. In this way, layers are superimposed to complete the printing work of a three-dimensional entity.

3. Application of SLA light curing equipment

SLA light-curing molding method is the earliest rapid prototyping manufacturing process, which is highly mature and has passed the test of time. The prototype is directly made from the CAD digital model, the processing speed is fast, the product production cycle is short, no cutting tools and molds are required, and the prototypes and molds with complex structures or shapes that are difficult to form using traditional methods can be processed. Visualize CAD digital models and reduce the cost of bug fixes. Provide samples for experiments, and verify and check the results of computer simulation calculations. The SLA rapid prototyping method can be used for transparent resin materials and the molding surface quality is smooth, but due to the low strength of the molded parts, the characteristics of light pollution and strong odor during the molding process, it is mainly used in: automotive appearance parts and structural parts. Verification, wax models in precision casting, cultural and artistic fields, etc.

4. Advantages of SLA technology:

1. The light-curing molding method is the earliest rapid prototyping manufacturing process, which has a high maturity and has passed the test of time.

2. The prototype is directly made from the CAD digital model, the processing speed is fast, the product production cycle is short, and no cutting tools and molds are required.

3. It can process prototypes and molds with complex structures or shapes that are difficult to form using traditional means.

4. Visualize the CAD digital model and reduce the cost of error repair.

5. Provide samples for experiments, and can verify and check the results of computer simulation calculations.

6. It can be operated online and remotely controlled, which is conducive to the automation of production.

5. Disadvantages of SLA technology:

1. The cost of the SLA system is high, and the cost of use and maintenance is too high.

2. The SLA system is a precision device that operates on liquids and has strict requirements on the working environment.

3. Molded parts are mostly resin, with limited strength, stiffness and heat resistance, which is not conducive to long-term storage.

4. The preprocessing software and driver software have a large amount of calculation, and the correlation with the processing effect is too high.

5. The software system is complex to operate and difficult to get started; the file format used is not familiar to most designers.

DLP laser beam shaping process principle

In 1981, Hideo Kodama of Nagoya City Industrial Research Institute invented the use of photocurable polymers to 3D print solid models. In 1987, Larry Hornbeck of Texas Instruments (Tl) created DLP (Digital Light Processing) technology. DLP is used in projectors, equipped with digital micromirror devices, each mirror representing a pixel in the image to be displayed. Many devices use DLP technology, including projectors, movie projectors, mobile phones and 3D printers.

The working principle of DLP projection technology is: after the beam passes through a high-speed rotating color wheel (color separation device, a kind of prism), it is decomposed into three primary colors of R, G, and B, and then projected onto the DMD chip. There are many tiny mirrors on the DMD chip, and each small mirror can rotate freely between +10° and -10° and is positioned electromagnetically. After the signal is input, it acts on the DMD chip after processing to control the opening and deflection of the lens. After the incident light is reflected by the DMD lens, it is projected by the projection lens (optical lens) and projected on the large screen.

DLP printing technology (Digital Light Processing 3DPrinting), also known as FTI (Film Transfer Imaging). DLP3D printing technology is very similar to SLA3D printing technology. Liquid photosensitive resin (Resin) is used as the weekly printing material to print the object layer by layer. Support may also be required during printing, and the overall precision (accurate degree) is extremely high! The special feature of DLP3D printing technology is that the liquid photosensitive resin is cured by means of projector projection, and the finished product is printed.

Speed Compared with SLA, DLP3D printer digital projector can cure the whole layer of image at one time, so it can make each layer fast curing, while the laser in SLA printer must cure a single layer [point by point]. Therefore, DLP only needs to use a single shot of the layer image to cure, so the printing speed is faster.

The digital projector used as a light source in the precision DLP 3D printer is composed of pixels. Therefore, in DLP

The layer of a part printed on a 3D printer consists of many [3D pixels] called [voxels]. Voxels are the tiny bricks that together make up the layers of a part, and are so tiny that they are almost impossible to see.

Just imagine 3D pixels as LEGO bricks, the surface of the model formed by LEGO bricks, will not be 100% smooth, but DLP will still produce very beautiful and detailed parts. Of course, the fineness of the machine depends on the projector, and the current projector has been upgraded from 1080p to 2k, and then from 4k to 8k! The fineness of the latest DLP3D printers can also be lower than 50um.

Compared to SLA, the limitation of DLP is to print large and detailed parts. Because the size of the image determines the resolution. As the layer image size increases, the resolution also decreases, which means that when printing models of very large scale, detailed parts of the model may be affected.

First, the 3D model will be cut horizontally into layers by the 3D printing software, and then the projector will project the shape pattern of the first layer model onto the liquid photosensitive resin, and then undergo photocuring and molding. After the first layer is completed, the object will be raised slightly, and then the shape pattern of the next layer model will be projected onto the photosensitive resin, and the model will be printed out in layers.

Both DLP3D printing technology and SLA3D printing technology use liquid photosensitive resin (Resin) as the weekly printing material. The printing cost is relatively expensive, but the printing precision is extremely high, which is very suitable for model making, jewelry Prototype and other products with high precision, or For mold use.

Firstly, the three-dimensional solid model is designed and conceived according to CAD, and the solid model is sliced by discrete programs, and the shape of the irradiation is designed, and the formed data information will precisely control the movement of the light source and the lifting platform; then, the relative distance of the lifting platform falls, After the light-cured layer is covered with another layer of liquid resin, the second layer is irradiated, and the second layer is firmly bonded to the previous cured layer, and stacked layer by layer to form a three-dimensional product prototype. Secondly, the laser releases the relative shape of the light spot according to the shape of the slice, and completes the production and processing of the sheet after curing the resin; the prototype is taken out of the resin, finally cured, and then polished, electroplated, painted or colored to obtain the desired product.

Advantages of DLP molding process

Not only the forming precision is high and the quality is good, but also the surface of the molded object is smooth and delicate. Its molding speed is relatively fast, and it is much faster than the SLA molding process.

DLP molding process defects

DLP models of high-precision light-curing 3D printers are expensive, and if they are industrial-grade, the price will be even higher. The resin material used by DLP is relatively expensive, which is easy to cause waste of raw materials. Body photosensitive materials must be closed to light during use and storage.

The difference between DLP and SLA

DLP3D printing and SLA3D printing belong to the same category, and the process is relatively similar, and there is basically no difference in product characteristics and application categories. However, both have certain differences in light source. The former uses a high-resolution digital light processor (DLP) projector to irradiate the liquid photopolymer step by step, and each layer is cured in the form of a slide. . The SLA processing technology is that the laser beam scans and solidifies from point to line and from line to surface. So DLP is faster than comparable SLA stereolithography printers.

DLP 3D printing resin

Whether it is the SLA process or the DLP process, the biggest problem of the light-curing 3D printer is the resin problem, and the key to the solution is to balance the curing speed, hardness, flexibility and other characteristics. In the field of high-end applications where product characteristics must be high, photosensitive resins for SLA/DLP have been monopolized by foreign countries for a long time.

LCD is an emerging technology in 3D printing technology. It has become popular in recent years. Based on DLP, it is researched and developed, and the cost is greatly reduced. The working principle of the LCD 3D printer is to use the LCD imaging principle of the liquid crystal screen. Driven by the computer and the display circuit, the computer program provides an image signal, and a selective transparent area appears on the LCD screen. The ultraviolet light passes through the transparent area and irradiates the resin. The photosensitive resin consumables in the tank are exposed and cured. After the curing time of each layer is over, the platform support lifts the cured part to allow the resin liquid to replenish and reflow. The platform descends again, and the thin layer between the model and the release film is exposed to ultraviolet light again. As a result, it is solidified layer by layer and printed into an exquisite three-dimensional model. Therefore, the LCD 3D printer that forms images through this principle is also called "LCD 3DPrinter.

LCD (Liquid-crystal display) printing technology is a new technology that has only emerged in recent years, and it is sometimes called DUP (Direct UV Printing).

The core working principle of all LCD 3D printers is the same: they illuminate the 3D printed cross-section by using an LCD screen to shade a UV light source. Essentially, this replaces the DLP projector unit and replaces the DLP with a more compact and less expensive screen, at the expense of print resolution and printer durability. So, LCD screens may wear out over time, while DLP projectors will last longer. The theoretical service life of the latest black and white screen LCD is more than 2000 hours, which is greatly improved compared with the previous color screen (the original color screen is basically less than 500 hours).

In 3D printing technology, compared with FDM mature technology developed for more than ten years and SLA and DLP technology with obvious advantages in mid-to-high-end applications, LCD technology has just begun. Counting the first DIY equipment in 2013 or the first commercial product in 2014, it was only a few years ago, so the maturity is far less mature than other technologies, and there are only a handful of equipment types.

working principle:

The simplest understanding of LCD printing technology is that the light source of DLP technology is replaced by LCD. We can review the characteristics of photocuring technology. The core of each photocuring technology is the solution around the light source, from SLA for laser scanning, to DLP for digital projection, to the latest LCD printing technology. LCD technology is divided into two types, and the two are not the same. The dividing line is the wavelength of the light source, one is 405nm ultraviolet, and the other is 400-600nm visible light. LCD mask photocuring: use 405nm ultraviolet light (same as DLP), plus LCD panel as a selective light transmission technology, it is LCD masking technology (LCD masking) or there are many names in the industry, such as choosing digital light processing (mDLP), liquid crystal DLP technology, UV mask curing and more.

With LCD printing, you can get DLP comparable speeds, and the equipment is lighter, smaller, and less expensive.

Features of LCD light curing 3D printing technology:

1. High precision

The resolution of LCD light-curing 3D printers can reach 4K or even 8K, and the precision can reach 100 microns, which can be said to be very high precision, and it is also superior to SLA technology in terms of printing technology, but at present the The application of the technology is still relatively rare, because its LCD monitors need to be replaced too frequently.

2. Cheap price

LCD light-curing 3D printer adopts open source technology, and its equipment components are cheaper than SLA, DLP and other process technology printers. It is the most cost-effective light-curing printer among all kinds of printers on the market. It is very suitable for beginners to buy as an entry-level printer. .

3. Simple operation

The LCD light-curing 3D printer does not have a projection module like SLA and DLP, but only a high-resolution transparent screen. Its structure is simple and easy to assemble. It is also very easy for novices to operate by themselves, and the maintenance of LCD light-curing 3D printers is also very simple in the later stage of equipment. You only need to simply look at the maintenance process to manage the equipment well.

4. Use more consumables

LCD light-curing 3D printers are similar to DLP technology. The resin consumables used in it are basically universal except for SLA-specific consumables, and have very good compatibility. After purchasing, users don't need to worry about not being able to buy suitable consumables when using LCD light-curing 3D printers.

advantage:

①High precision: SLA<LCD<DLP

②Cheap price, high performance-price ratio

③Simple structure, easy to assemble and maintain

④Universal resin

⑤ Multiple products can be printed at the same time

shortcoming:

① The range of options is small

②The print size is small

LCD curing technology is slightly later than DLP technology. Volkswagen's display technologies include panels and projections, both of which were developed more than ten years ago. DLP can withstand and process 405nm light waves, so there is 3D printing DLP technology. In the same way, a small number of LCD panels can withstand 405nm ultraviolet rays, so there is the technology of LCDmasking. Regardless of whether it is 405nm or visible light, LCD technology will eventually break the problem of DLP being large and thick/small and fine, because there are already many cheap and high-volume LCD machines that directly use 2K screens.

LCD technology has a flaw: the light efficiency is not as high as DLP. However, by increasing the brightness of the 405nm lamp to achieve more luminous flux, or a visible light LCD with ordinary luminous flux and a high-sensitivity resin, the curing speed obtained cannot be compared with the molding speed of DLP. There is an actual reference value, the same 100 micron thick curing, DLP takes a few tenths to a few seconds to cure, and 405nm ultraviolet LCD or visible light LCD needs more than ten seconds to tens of seconds to cure. Here is a new solution, using projection other than DLP plus visible light technology to achieve a high speed within one second. Projection can simultaneously achieve high speed, large size, high precision, and low cost, but it has not yet been commercialized.

2018

100+

10000㎡

100+

+86 19958086067

sales@3dacme.com