There are significant differences between industrial 3D printers and CNC machining in many aspects

There are significant differences between industrial-grade 3D printers and CNC machining in many aspects. These differences are mainly reflected in technical principles, application scenarios, cost-effectiveness, and future development trends. Here's a detailed comparison of the two:

1. Technical principles

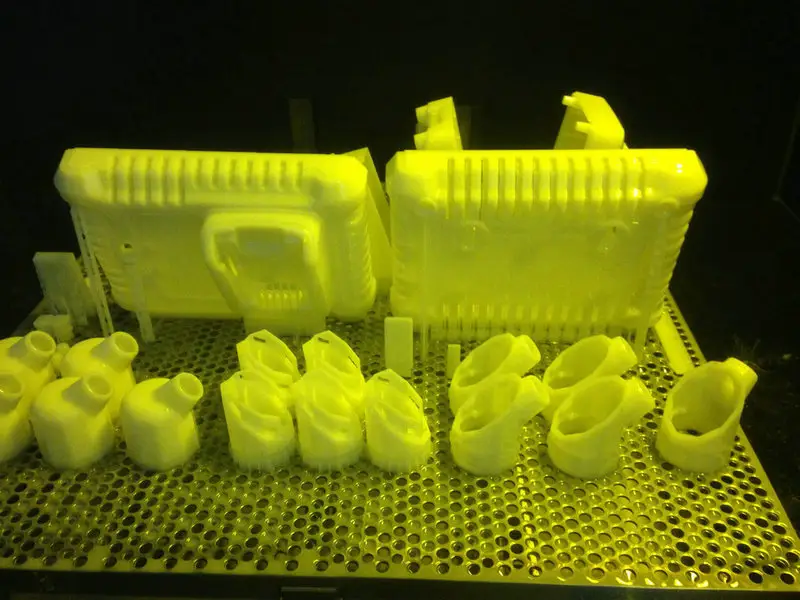

Industrial-grade 3D printer: uses additive manufacturing technology to build three-dimensional objects by stacking materials layer by layer. It does not require molds and can quickly form complex structures and fine surfaces, making it especially suitable for personalized customization and rapid prototyping. Industrial-grade 3D printers usually have higher printing speed, larger printing size, higher precision and stronger stability, and can meet the requirements of industrial manufacturing.

CNC machining: Use CNC machine tools to perform metal cutting, drilling, milling and other processing operations. Pre-programmed computers control the machine tool movement to achieve high-precision and high-efficiency processing. CNC machining can process a variety of metal materials, including stainless steel, aluminum alloys, etc., and can achieve full-process production from a single piece to a complete piece.

2. Application scenarios

Industrial-grade 3D printers: widely used in manufacturing, medical fields, art and culture fields, education fields, and research fields. In the manufacturing industry, it can manufacture complex-shaped parts and product prototypes; in the medical field, it can manufacture high-precision medical equipment, prostheses, and implants; in the art and culture field, it can manufacture cultural relic replicas, sculptures, etc.; In the field of education, it can provide students with a more intuitive and vivid learning method; in the field of research, it can provide precise and efficient tools for scientific research.

CNC machining: It is also widely used in many industries, including automobile manufacturing, aerospace industry, heavy machinery manufacturing, medical industry, and electronic and communication equipment manufacturing. CNC machining can meet the needs of these industries for high-precision and high-efficiency processing, especially in situations where large-scale and batch production are required.

3. Cost-effectiveness

Industrial-grade 3D printers: have significant advantages in personalized customization and rapid prototyping, which can significantly shorten the product development cycle and reduce trial production costs. However, it may not be as cost-effective as CNC machining for high-volume production. In addition, the material cost of industrial-grade 3D printers is relatively high, and although the printing speed is improved compared with traditional processes, it may still be limited in some cases.

CNC machining: more cost-effective in large-scale, batch production. By optimizing the production process and reducing manual intervention, CNC machining can significantly reduce production costs and improve production efficiency. However, the manufacturing cost of CNC machine tools is high, and molds or fixtures need to be designed and manufactured in advance, which increases the initial investment cost to a certain extent.

4. Future development trends

With the continuous advancement of technology and changing market demands, industrial-grade 3D printers and CNC machining are constantly developing and improving. Industrial-grade 3D printers will continue to improve in terms of material selection, printing speed and accuracy to meet a wider range of application needs. At the same time, with the development of smart manufacturing and the industrial Internet, industrial-grade 3D printers will be more closely integrated into the smart manufacturing system.

CNC machining will also continue to develop towards high precision, high efficiency, and high automation. By introducing more advanced CNC systems and intelligent technology, CNC machining will further improve production efficiency and processing quality, and reduce production costs. In addition, with the advancement of intelligent manufacturing, CNC machining will be combined with other intelligent manufacturing technologies to form a more complete intelligent manufacturing solution.

To sum up, industrial-grade 3D printers and CNC machining each have their own unique advantages and scope of application. When choosing, you need to comprehensively consider factors such as specific application scenarios, cost-effectiveness, and future development trends.