In today's rapidly changing manufacturing environment, the iteration speed of product design is directly related to the market competitiveness of enterprises. As an important inspection link before product finalization, the production efficiency and precision of the prototype directly affect the cycle and cost of product development. The

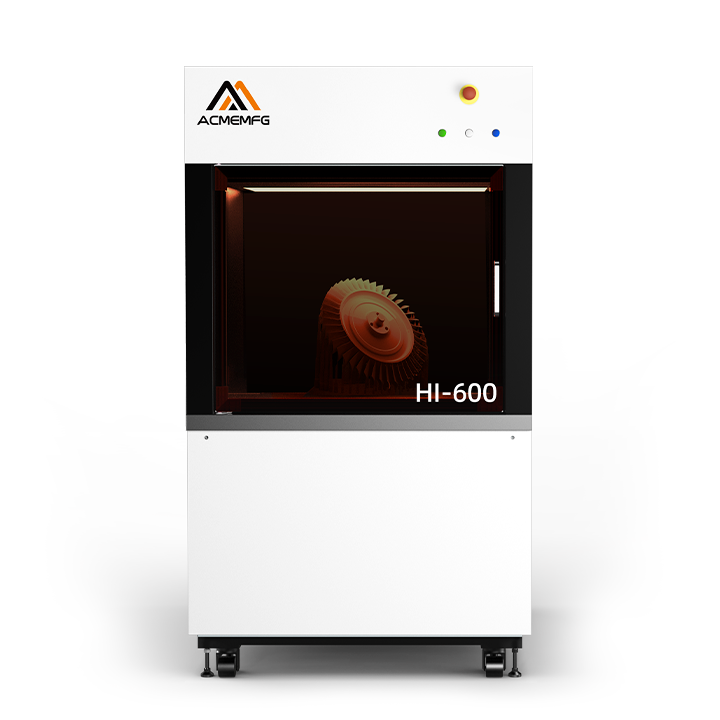

SLA (stereolithography) 3D printer, with its unique technical advantages, has shown great potential and value in the field of prototype production, and has become a powerful tool to promote product design innovation and quickly respond to market demand.

Overview of SLA 3D printing technology

SLA 3D printing technology, as a kind of photocuring molding technology, uses a high-precision laser beam to irradiate liquid photosensitive resin to solidify it layer by layer. This process does not require mechanical cutting or mold making, and directly builds a complex and delicate solid model based on three-dimensional design data. The core of SLA technology lies in its high precision, high resolution and ability to handle complex geometric shapes, which makes it stand out in prototype production.

Efficient and fast, shortening the development cycle

Traditional prototype production often requires multiple links such as design, mold opening, and injection molding, with a long cycle and high cost. SLA 3D printers can complete the production of prototypes in a few hours to a few days, greatly shortening the product development cycle. Designers can quickly obtain physical models for appearance inspection, structural verification and functional testing, thereby accelerating the iterative optimization of products.

High precision, meeting industrial requirements

SLA 3D printers are known for their excellent precision, and the dimensional accuracy of plastic samples can reach ±0.1mm or even higher. This high precision ensures a high degree of consistency between the prototype and the final product, helping designers to discover and solve problems in the early stages and reduce the cost and time of later design changes.

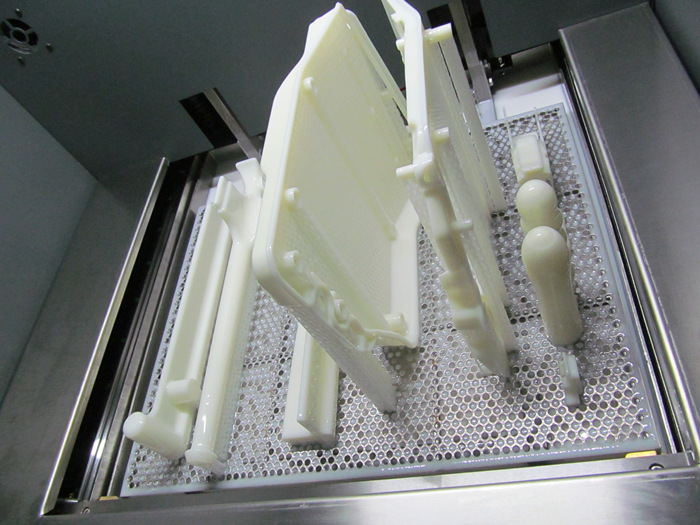

Complex structures, easy to achieve

Prototypes often contain many complex geometric shapes and internal structures, which are difficult to handle with traditional manufacturing methods. SLA 3D printing technology can easily cope with these challenges and directly print prototype models with complex structures and fine details. This provides designers with greater creative space, allowing them to explore design concepts more freely and promote product innovation.

Diverse materials and excellent performance

SLA 3D printing supports the selection of a variety of photosensitive resin materials with different physical and chemical properties, such as strength, toughness, transparency, etc. Designers can choose the right material according to the specific needs of the prototype to obtain the best test results. In addition, SLA printing has a high material utilization rate, which reduces waste and reduces costs.

Multi-material printing, simulating real environment

Some high-end SLA 3D printers also support multi-material printing, which can print material areas with different properties on the same prototype. This capability enables the prototype to more realistically simulate the use environment and performance of the final product, providing designers with more comprehensive and accurate test data.

Practical cases of SLA 3D printers in prototype production

Taking the automotive manufacturing industry as an example, SLA 3D printers play an important role in the production of automotive prototypes. Designers can use SLA technology to quickly print prototype models such as automotive exterior trims, interior trims, and complex mechanical structural parts. These prototypes are not only used for appearance verification and structural evaluation, but also for advanced tests such as wind tunnel tests and collision simulations. Through SLA 3D printed prototypes, automakers can discover potential design problems in advance, optimize product performance, and improve market competitiveness.

In addition, SLA 3D printers are also widely used in prototype production in consumer electronics, medical devices, aerospace and other fields. Its high efficiency, precision and flexibility have brought significant advantages and convenience to the product development of these industries.

Conclusion

The application of SLA 3D printers in the field of prototype production has demonstrated its strong technical strength and broad application prospects. With the continuous advancement of technology and further reduction of costs, SLA 3D printing technology will play an important role in more fields, promoting innovation in product design and transformation and upgrading of the manufacturing industry. For companies that pursue high efficiency, precision and rapid response to market changes, SLA 3D printers are undoubtedly the ideal choice in the field of prototype production.