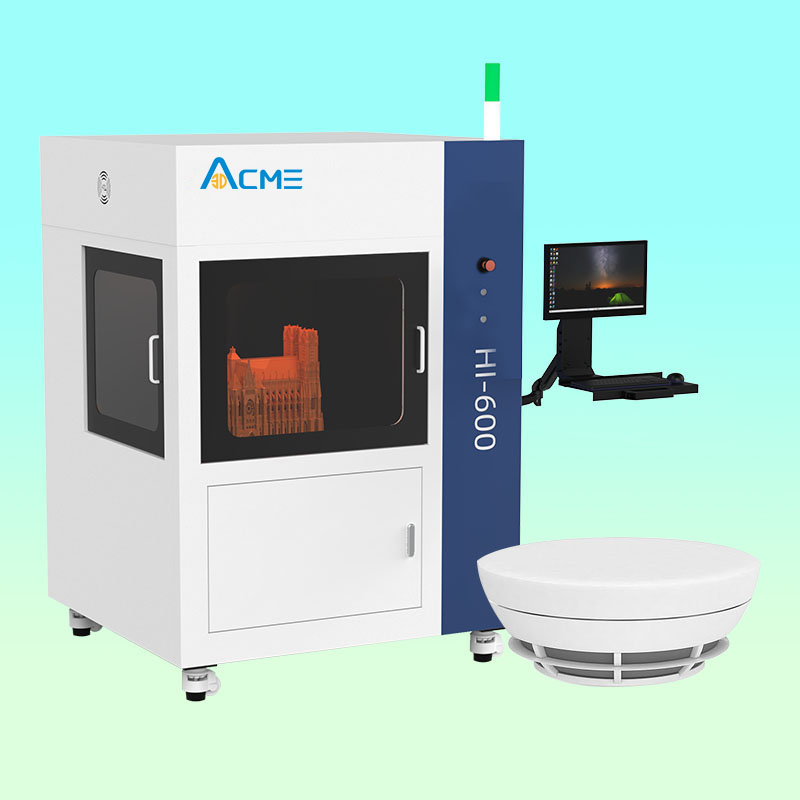

Guardian in the Spark: 3D Printed Pyrotechnic Alarm Prototype Model Driven by Industrial 3D Printer

In modern society, fire safety has always been the focus of attention. In order to protect the safety of life and property, ACME has developed an innovative 3D printed smoke and fire alarm hand model with the help of

industrial 3D printers. This hand model has excellent functionality and safety, but also incorporates the selling points of ACME products to provide users with comprehensive protection and convenience.

With the continuous advancement of science and technology, 3D printing technology is gradually being applied in various fields, including the field of smoke and fire alarms. Driven by industrial-grade 3D printers, the manufacture and design of smoke and fire alarms has become more flexible and innovative. This article will explore the application of 3D printing in the field of smoke and fire alarms, and introduce the advantages and improvements it brings.

Innovative design inspiration:With the help of 3D printing technology, the design of smoke and fire alarms has become more innovative and diverse. Traditional fire alarms often have similar appearance and structure, but through 3D printing, designers can flexibly adjust the shape, size and appearance details of fire alarms to meet the needs and individual requirements of different users. This innovative design inspiration opens up new possibilities in the field of smoke alarms.

Customized production:3D printing technology makes the production of smoke alarms more customized. Traditional production methods usually require mass production of the same type of fire alarms, but 3D printing technology can manufacture unique smoke alarms one by one according to user needs. Such customized production can meet individual needs and improve product applicability and user experience.

Manufacture of complex structures:Smoke and fire alarms often require complex structures and internal components to achieve accurate fire detection and alarm functions. Traditional manufacturing methods may face the challenges of structural complexity and component connection, while 3D printing technology can easily manufacture complex structures and internal components through precise layer-by-layer printing to ensure the performance and reliability of smoke and fire alarms.

Rapid prototyping:Rapid prototyping is a crucial step in the research and development process in the field of smoke alarms. Traditional manufacturing methods may take a lot of time and cost to manufacture prototypes, but 3D printing technology can print out accurate prototype models in a short period of time, providing R&D teams with faster verification and improvement opportunities, and speeding up the product launch process .

The application of 3D printing technology in the field of smoke and fire alarms brings opportunities for innovation and improvement in this field. Driven by industrial-grade 3D printers, the design inspiration of smoke and fire alarms is released, the production process becomes customized and efficient, the manufacture of complex structures and internal components becomes easier, and rapid prototyping accelerates the product development process. With the continuous advancement of technology and the expansion of applications, we can expect that 3D printing technology will continue to play a greater role in the field of smoke and fire alarms, improving people's life safety and comfort.

The ACME 3D printed smoke and fire alarm hand model is driven by an

industrial 3D printer, achieving an innovative breakthrough in the field of fire safety. With its powerful alarm function, personalized design, innovative materials and manufacturing process, as well as the advantages of flexibility and convenience, this prototype model has become an important tool to protect people's lives and property safety. ACME will continue to be committed to promoting the development of 3D printing technology and bringing more innovative solutions to the society.