In the world of additive manufacturing, SLA (Stereolithography) 3D printing stands tall as a leading technology renowned for its unparalleled precision and intricate detailing capabilities. Whether you're a design enthusiast, engineer, or hobbyist,

SLA 3D printers offer a powerful toolset to transform your digital creations into tangible, high-quality objects. In this article, we will delve into the fascinating world of SLA 3D printing and explore its benefits, applications, and why it is a game-changer in the realm of additive manufacturing.

The Power of Photopolymerization:

The Power of Photopolymerization:At the core of SLA 3D printing lies the process of photopolymerization, a technique that involves curing liquid resin layer by layer using a precisely controlled light source, typically an ultraviolet (UV) laser. This laser selectively solidifies the resin, creating a three-dimensional object with extraordinary accuracy and detail. The ability to cure resin with pinpoint precision allows SLA printers to produce complex geometries and intricate designs that other 3D printing technologies may struggle to achieve.

Unmatched Precision and Surface Finish:SLA 3D printers excel in producing parts with exceptional precision and surface finish. With layer heights as low as a few microns, these printers can create objects with intricate features and fine details, resulting in a smooth and polished appearance. The high resolution of SLA printing ensures that every curve, contour, and edge of the model is faithfully reproduced, making it a preferred choice for applications that demand the utmost precision, such as jewelry, dental models, and prototyping.

Diverse Material Selection:

Diverse Material Selection:SLA technology offers a wide range of materials, each tailored to specific application requirements. From standard resins suitable for general-purpose use to specialized formulations engineered for specific properties like flexibility, transparency, or biocompatibility, there is a material for every need. This versatility opens up a vast array of applications across industries, including engineering, healthcare, consumer products, and more.

Applications Across Industries:

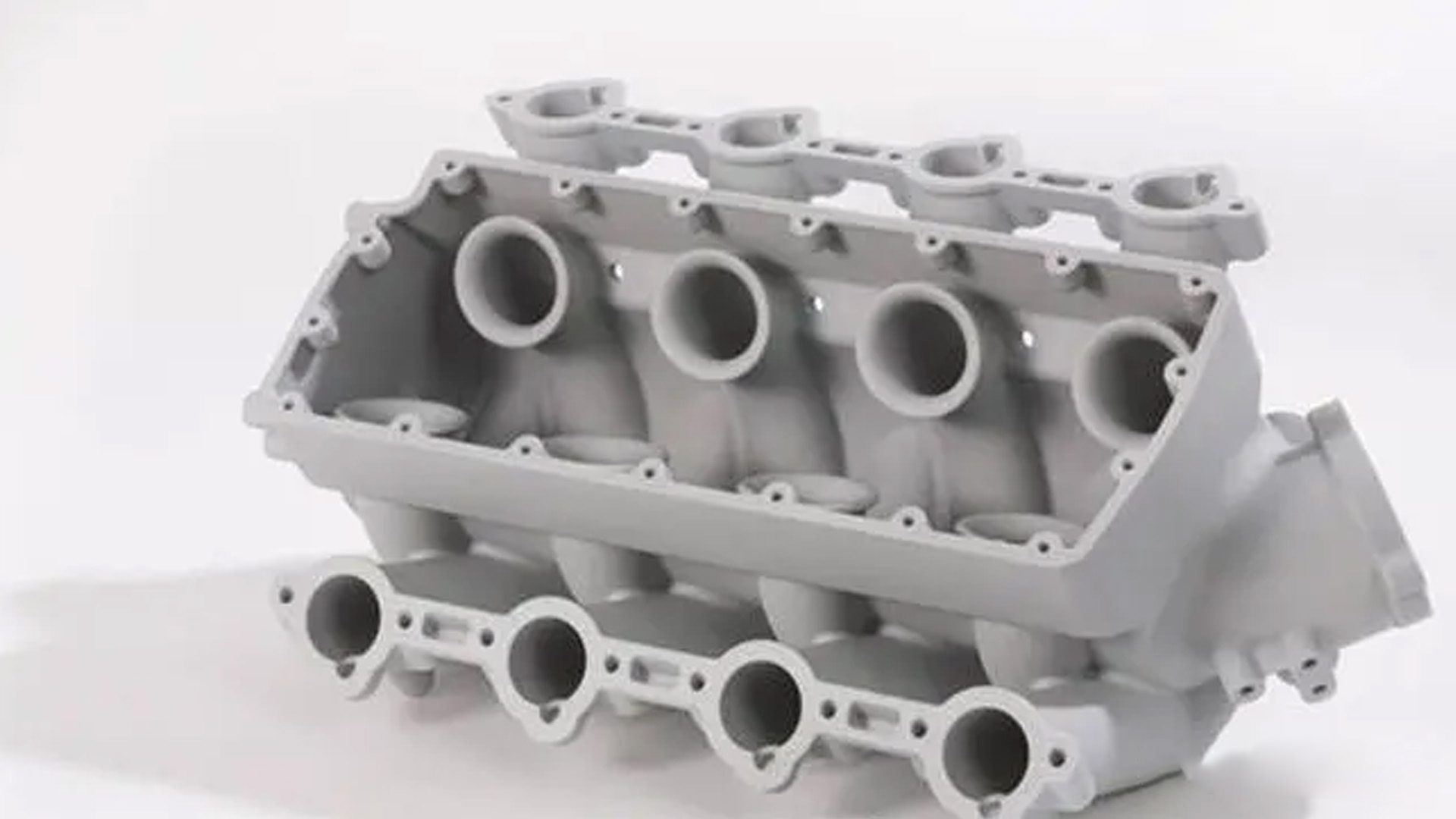

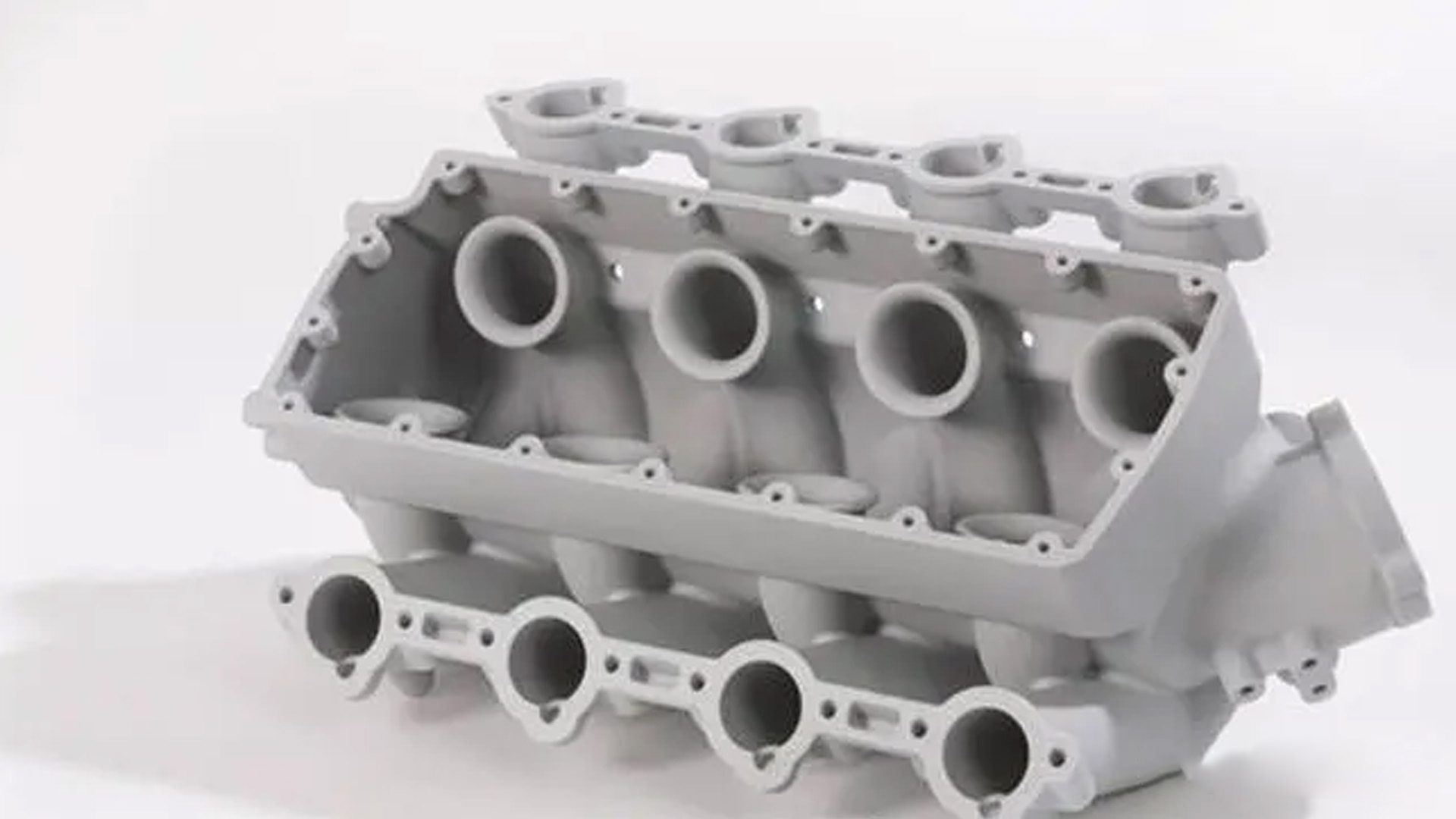

Applications Across Industries:SLA 3D printing finds applications in various industries, revolutionizing traditional manufacturing processes. In automotive and aerospace industries, it enables the creation of complex prototypes, functional components, and custom tooling with reduced lead times. Jewelry designers utilize SLA printers to bring intricate and detailed designs to life. The dental field benefits from the production of highly accurate and patient-specific models, surgical guides, and aligners. Architects and product designers rely on SLA printing to create stunning architectural models and prototypes that aid in visualization and product testing.

SLA 3D printing has established itself as a powerful tool for those seeking precision, detail, and exceptional surface finish in their 3D-printed objects. Its ability to create complex geometries, diverse material selection, and applications across industries make it an indispensable technology in the realm of additive manufacturing. Whether you're an engineer, artist, or innovator,

SLA 3D printers empower you to unleash your creativity and bring your ideas to life with unmatched precision and quality.