What is the 3D printing casting process, and what are the types of 3D printing used in the foundry industry?

Industrial-grade 3D printers are more and more widely used in the field of casting, and their advantages are mainly reflected in the rapid design and manufacture of high-precision casting models and samples, while reducing manufacturing time and costs. At present,

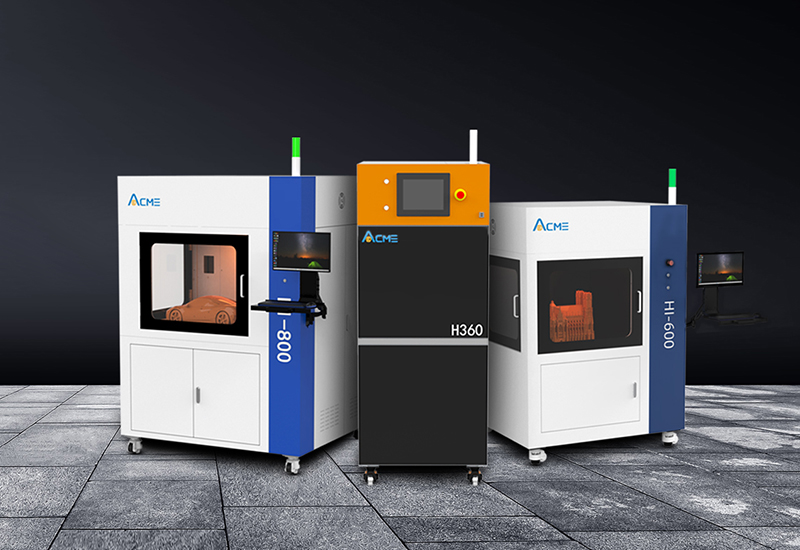

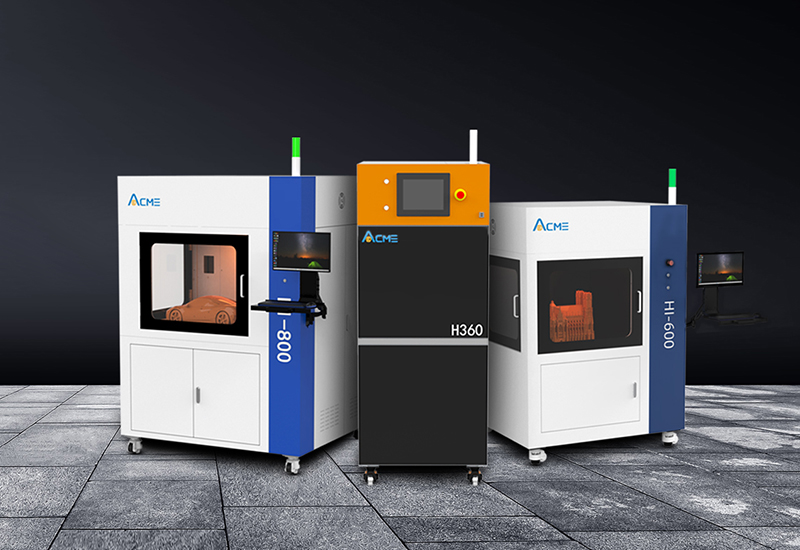

industrial-grade 3D printers can be applied to various aspects of the casting process, such as producing casting models, making complex parts, and manufacturing customized products. In addition, 3D printing technology can also make the design of castings more flexible, so as to achieve a more efficient and environmentally friendly production mode. Manufacturers such as ACME have also developed a variety of 3D printers suitable for casting, providing more choices for the casting industry.

What is 3d printing casting process:

3D printing casting process is a new casting process that combines 3D printing technology with traditional casting process. It uses a 3D printer to print out the required part model layer by layer on the resin, and then uses a traditional casting process to cast the part model into an actual part. This process can improve the precision of the casting process, reduce waste, shorten the production cycle, and can produce parts with complex shapes.

What are the types of processes that 3d printing is used in the foundry industry:

In the foundry industry, 3D printing technology can be applied to many different process types. The main applications include the following:

Model manufacturing: Using 3D printing technology to manufacture casting models can replace traditional hand-made methods, reduce manufacturing costs, shorten manufacturing cycles, and more accurately manufacture models of complex shapes.

Mold manufacturing: Using 3D printing technology to manufacture casting molds can improve manufacturing efficiency and reduce manufacturing costs. At the same time, more complex molds can be manufactured to meet the production needs of complex castings.

Manufacturing of castings: Using 3D printing technology to manufacture castings, castings of various shapes can be manufactured more quickly and accurately, and at the same time, it can reduce the scrap rate and reduce production costs.

The above are only some common application process types of 3D printing in the foundry industry, and the actual application needs to be selected and adjusted according to the specific situation.

The

industrial-grade 3D printers provided by ACME can be used in many fields of the foundry industry, such as rapid manufacturing models, casting processing and repair, industrial design, etc. Among them, the rapid manufacturing model is a widely used method, which can directly print out the model for casting by using 3D printing technology, which shortens the manufacturing cycle and reduces the manufacturing cost. In addition, 3D printing technology can also be applied to the processing and repair of castings, and the castings can be customized through the precise model printed by 3D, which improves the quality and production efficiency of castings.