ACME 8K 10.1-inch dental 3D printing helps digital upgrade in the field of dental casting

Dental digitization refers to the process of transforming traditional manual operations into digitization, so that digital equipment such as 3D scanners, CAD software, 3D printers, etc. can help dentists and technicians to complete the diagnosis, treatment and treatment of teeth faster and more accurately. Production process. This digital process can greatly improve the efficiency and accuracy of dental care, and at the same time, it is more convenient and comfortable, and can provide patients with a better dental treatment experience.

Advantages of standardization and digitization

standardization

3D printing technology can quickly produce parts and products that meet specific standards and specifications. This is because 3D printing technology can precisely control the distribution and shape of materials to ensure that the size and shape of the produced products meet the specification requirements. At the same time, because 3D printing technology can realize rapid iterative design and production, it can respond to market changes and customer needs faster, and improve the flexibility and competitiveness of enterprises.

Digitizing

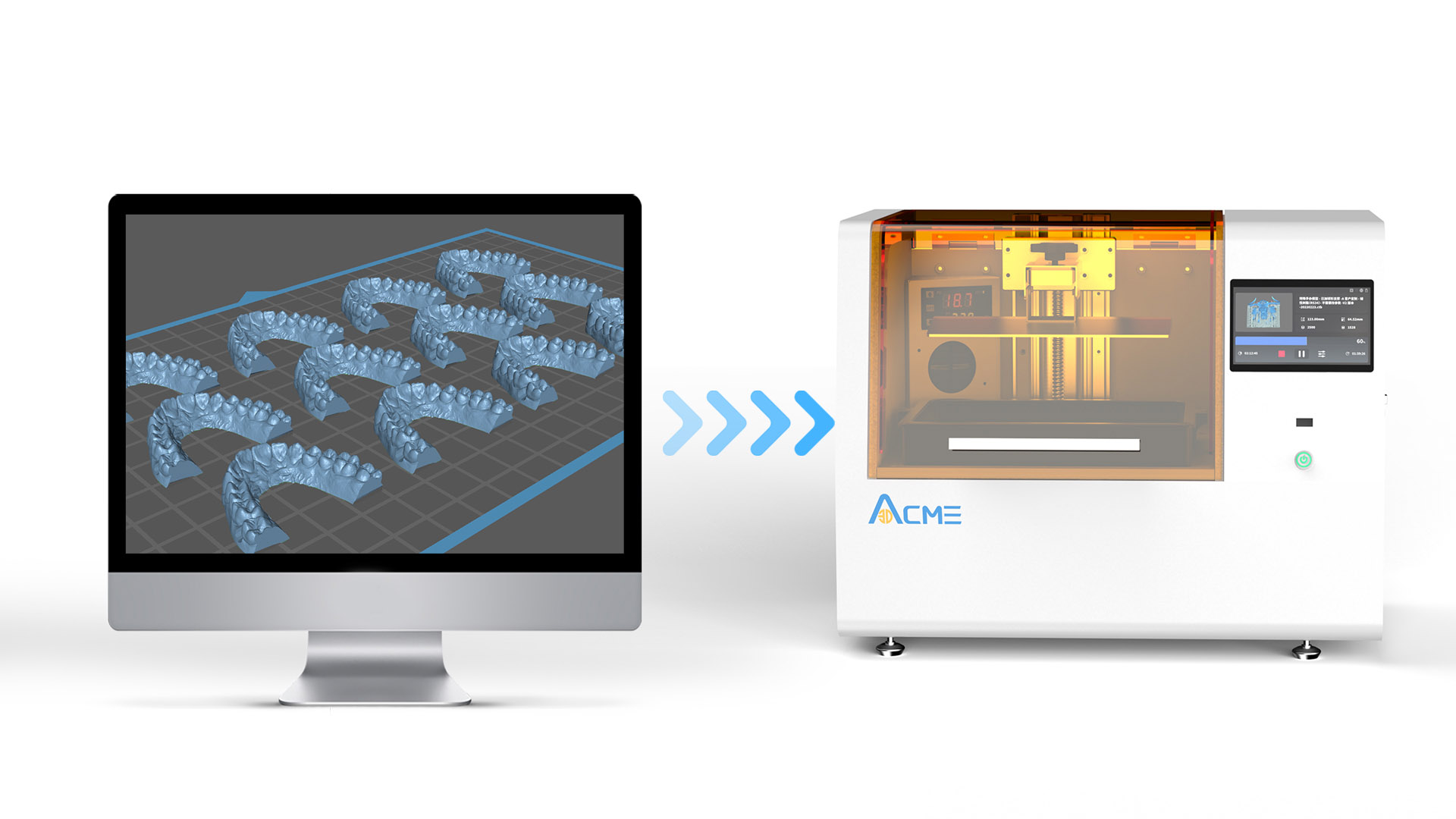

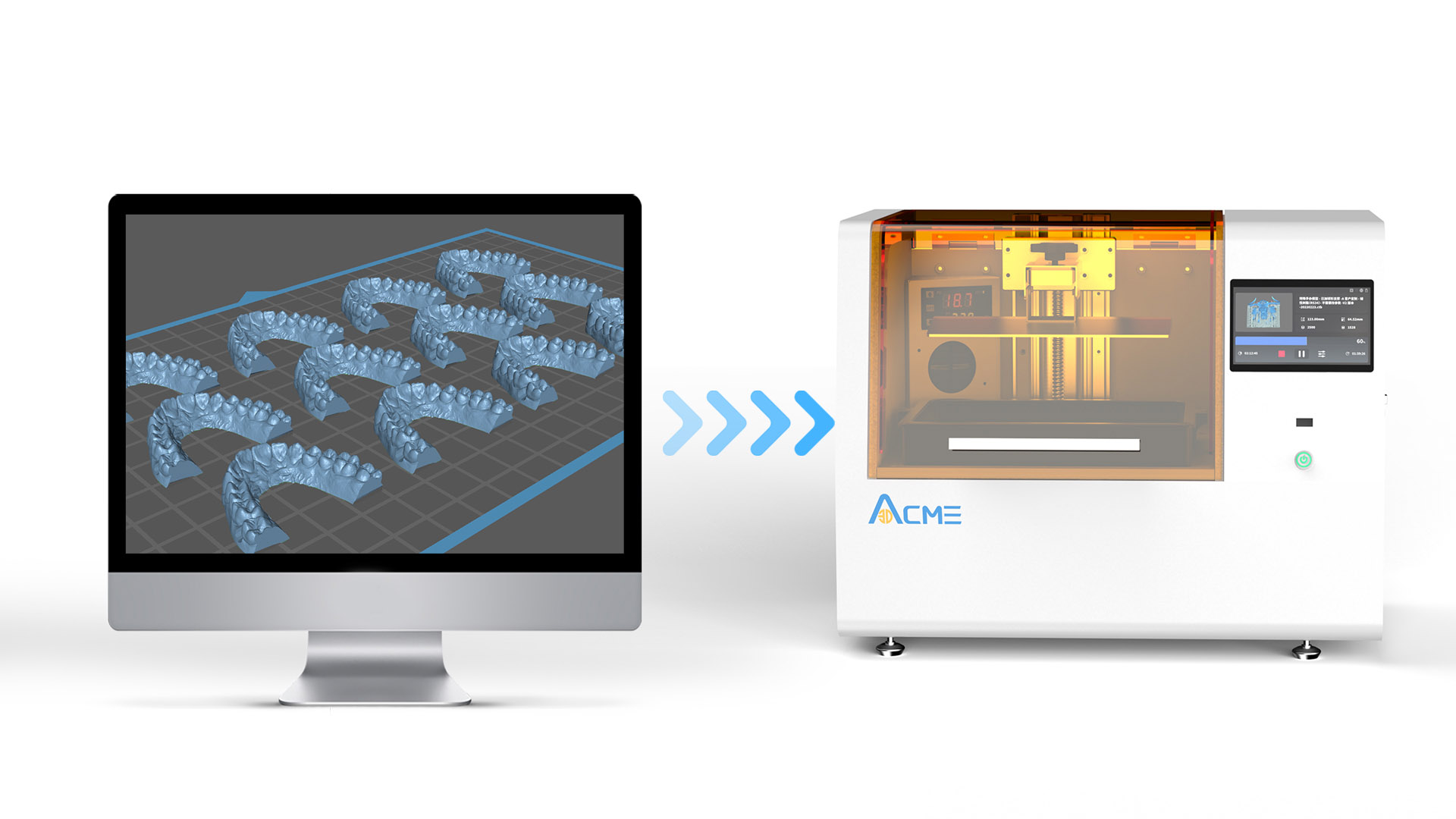

3D printing technology can realize digital production, that is, to directly convert digital design files into physical products. This avoids steps that require manual processing and adjustments in the traditional production process, thereby improving production efficiency and precision. At the same time, digital production can also realize personalized production, that is, customize the production of products according to customer needs, meet the individual needs of different users, and bring more business opportunities for enterprises.

What is casting dental model

Casting dental molds is a technique for making dental restorations by injecting molten metal or ceramic material into a dental mold and allowing it to solidify into a restoration that matches the shape of the tooth. Cast dental models are commonly used to create restorations such as metal-ceramic crowns, metal bridges, metal and porcelain abutments. Casting a dental model requires first making a model of the teeth and gums around the affected tooth, then using plaster and other materials to make an accurate dental model, and finally injecting molten metal or ceramics into the dental model to make a restoration.

In the traditional process of casting dental models, it is necessary to make a metal dental model that can completely match the shape of the patient's oral cavity through manual carving or mechanical processing. The use of 3D printing technology can produce high-precision cast dental models more quickly, and can also store oral morphology data digitally, which is convenient for subsequent review and restoration.

Digitization of Casting Dental Models

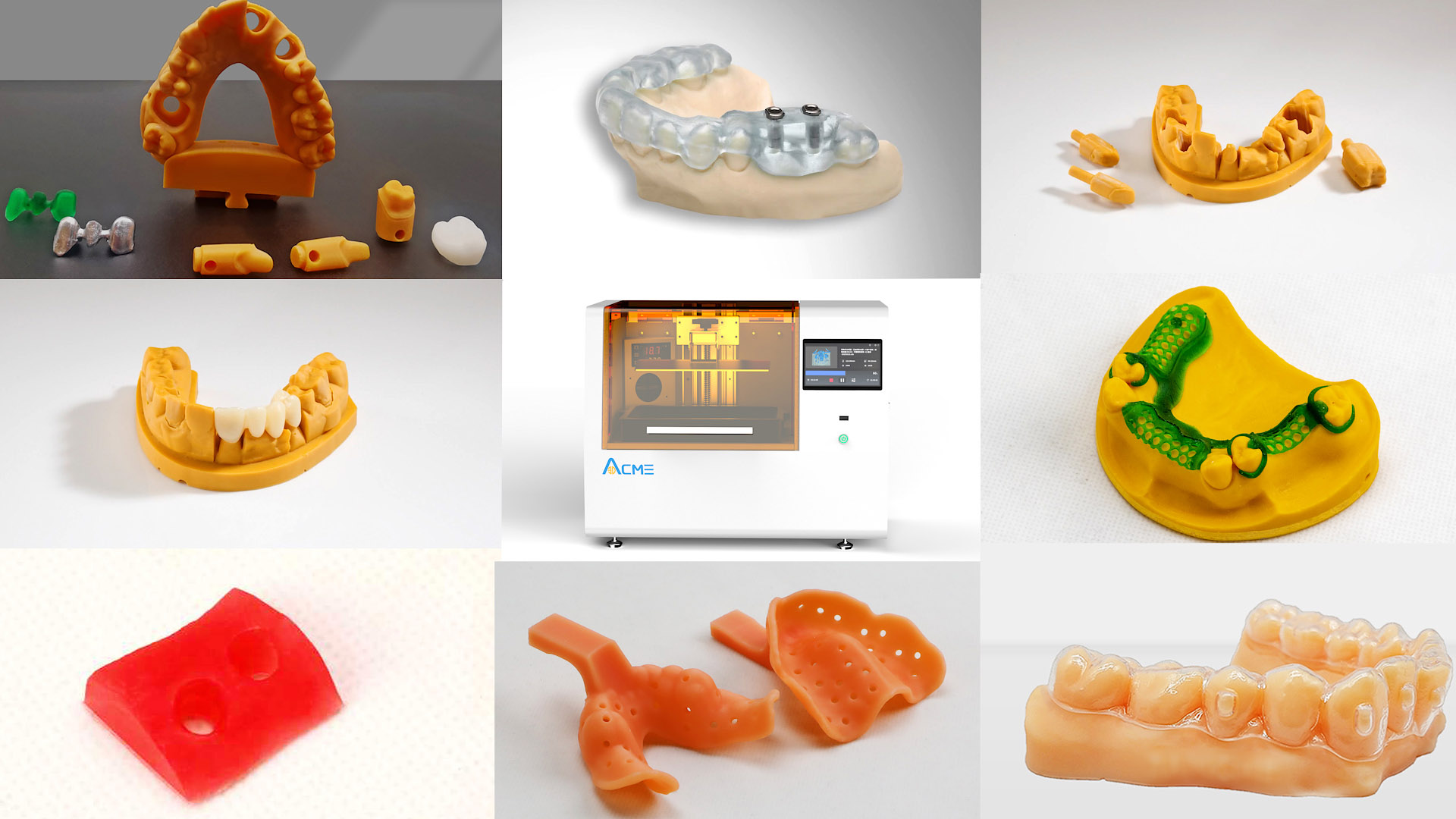

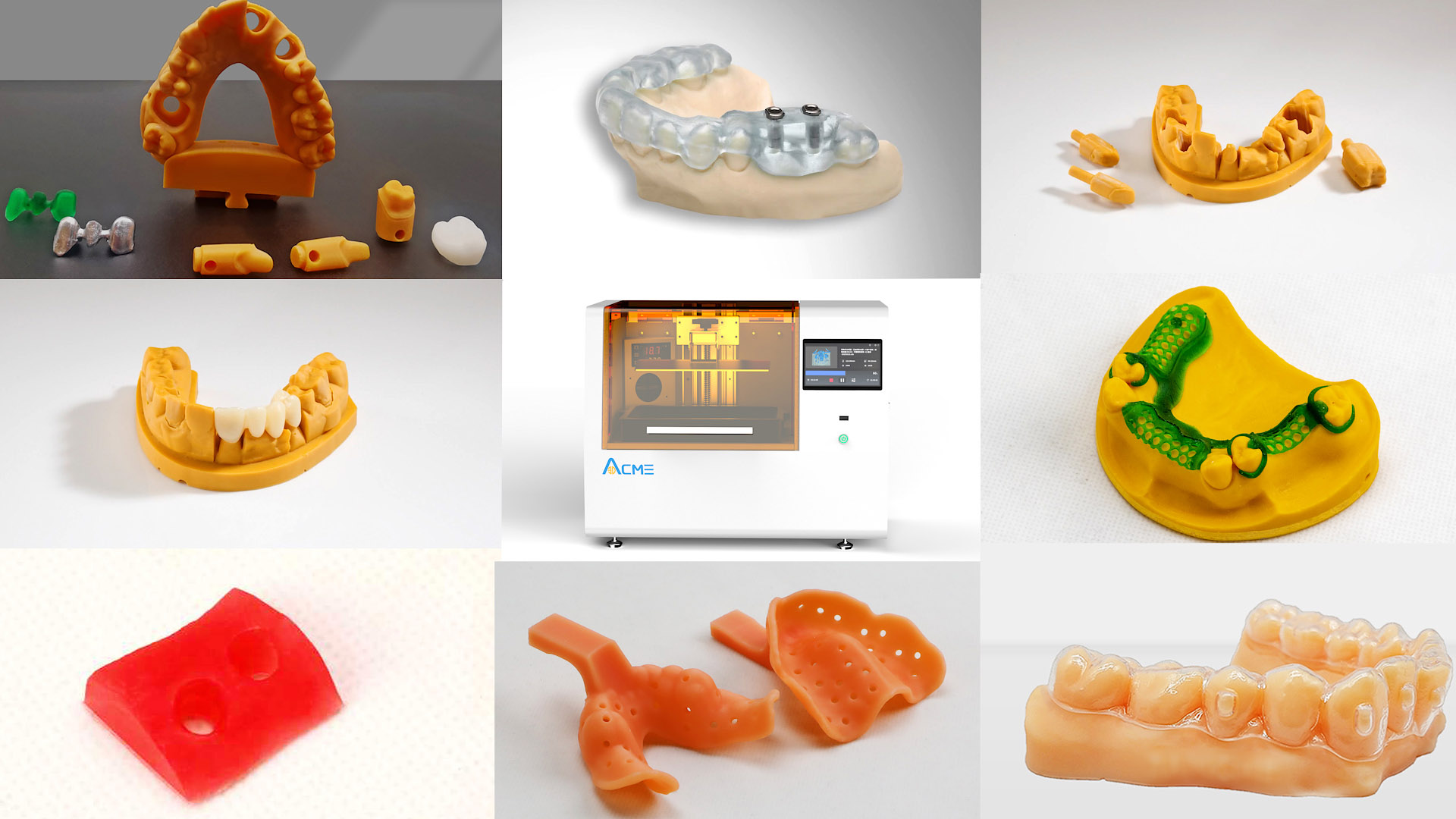

Digital casting dental model refers to the process of using 3D scanning or CAD software to design a digital model, converting the digital model into a solid model through 3D printing technology, and then using casting technology to convert the solid model into a casting dental model. Digital casting dental mold technology can greatly shorten the production time, improve accuracy and repeatability, and reduce material waste and environmental pollution in the traditional casting dental mold process. In addition, digital casting of dental models can also make it easier for doctors and technicians to communicate and collaborate, thereby improving patient outcomes.

ACME

dental 3D printer R3 pro is a 3D printer specially used for dental applications. It adopts LCD light curing technology, which can realize high-precision and high-efficiency dental mold printing, and is suitable for oral dental mold casting, restoration, implantation, orthodontics and other fields. The printer adopts liquid light curing technology, 8K 10.1-inch ultra-high-definition LCD screen, 7680*4320 ultra-high resolution and 380:1 high contrast ratio, high light transmission performance of 6.2%, and a service life of up to 2000h, which is 6 times higher than that of color screens. times, the single-layer curing time can be shortened by 1~4s, which significantly improves the printing efficiency, restores the vivid details of the model, and can print dental models with high fineness and smooth surface. In addition, the printer is also equipped with self-developed dental 3D printing software, which can be customized according to specific needs for easy operation and management.