In recent years, 3D printing technology has developed rapidly, and its innovative applications in gold jewelry and other professional fields have continuously made breakthroughs, creating favorable opportunities for the personalization, digitization, and intelligence of the gold jewelry industry.

The process of printing jewelry with a

jewelry 3D printer is usually as follows:

Design: Use CAD or other 3D modeling software to design jewelry models, including shapes, details, sizes, etc.

Preparation: Import the designed model into the jewelry 3D printer software, and perform preparatory work such as slicing, support generation, and printing parameter settings.

Printing: inject printing material into the printer, start the printer, and start printing.

Cleaning: After printing, the model needs to be removed from the printing plate, supports and residues removed, and cleaned.

Post-processing: post-processing according to requirements, such as vacuuming, high-temperature dewaxing, casting, etc.

It should be noted that different jewelry 3D printers may have some differences, and the specific operation steps will also be different.

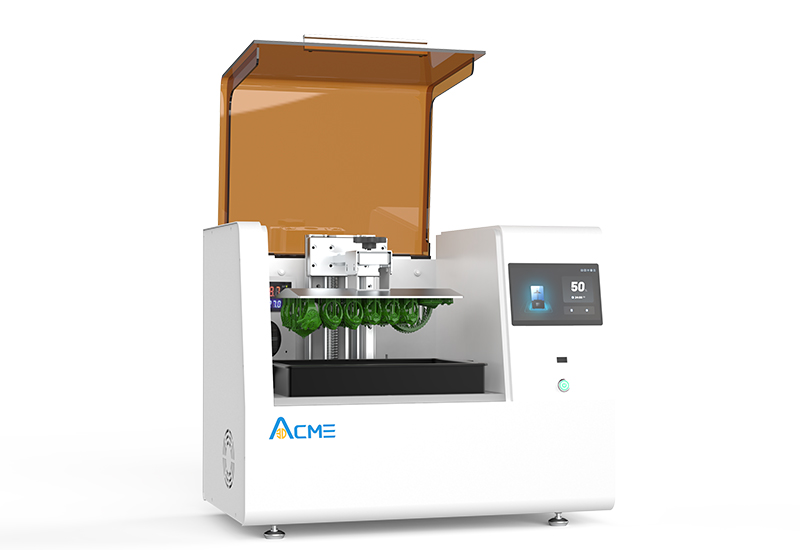

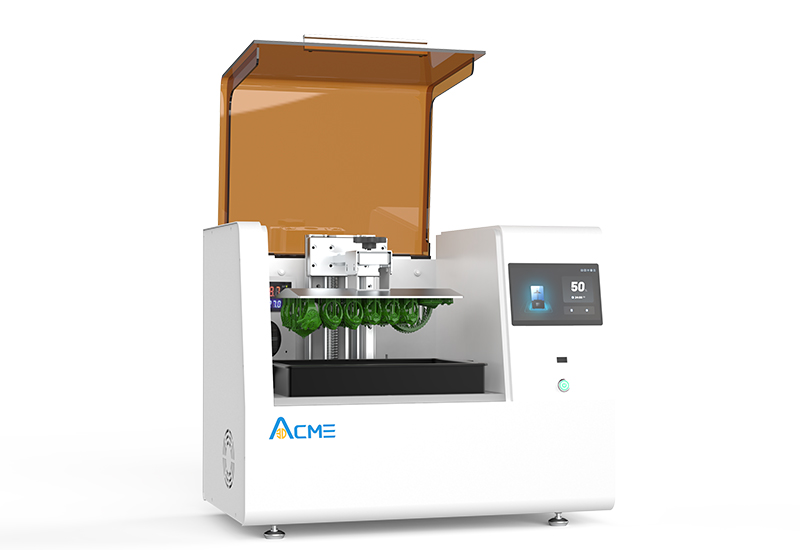

The advantages of ACME jewelry 3d printers in the jewelry industry include the following:

Improve production efficiency: Jewelry 3D printers can greatly shorten the production cycle, reduce the time and labor costs of traditional hand-made and casting, and improve production efficiency.

Improve precision and fineness: Jewelry 3D printers use high-precision light-curing technology to print complex, delicate, and fine jewelry models and parts, ensuring the precision and fineness of jewelry.

Low printing cost: Compared with traditional jewelry making methods, the material cost and labor cost of jewelry 3D printers are much lower.

Printing diversity: Jewelry 3D printers can make jewelry models of various styles, from traditional jewelry styles to modern popular designs.

Enhance design flexibility: Jewelry 3D printers can produce a variety of jewelry models in different styles according to customer needs and designer ideas, which enhances design flexibility and creativity.

Reduce production costs: The use of jewelry 3D printers can reduce the cost of jewelry production, including material costs, labor costs, and production cycle costs. At the same time, jewelry 3D printers can save more time and resources, achieve higher production efficiency and lower costs.

ACME

jewelry 3D printer printing jewelry has the characteristics of fast production speed, high production precision, low production cost, high degree of freedom in creative design and sustainable development, and has become an important means and trend of jewelry production.