With the popularity of 3D printers, light-curing 3d printers are gradually showing up in everyone's field of vision. Today, let's talk about this light-curing 3d printer.

Photocuring 3D printers can be mainly used in the following industries:

Industrial manufacturing: light-curing 3D printers can manufacture complex parts, prototypes, molds, etc., and can be used in aviation, automobiles, machinery and other fields.

Medical industry: Light-curing 3D printers can manufacture high-precision medical devices, prosthetics, orthodontics, etc., which are helpful for personalized treatment and surgery in the medical industry.

Education industry: Stereo-curing 3D printers can help students better understand and learn concepts, structures and shapes, etc., and improve learning interest and learning effects.

Culture and art industry: Stereo-curing 3D printers can produce high-precision artworks, replicas of cultural relics, architectural models, etc., for exhibitions, cultural heritage protection, etc.

Jewelry industry: Light-curing 3D printers can manufacture precise jewelry models and samples, improving the efficiency and accuracy of jewelry design and production.

Glasses industry: Stereo-curing 3D printers can manufacture highly customized glasses frames to improve the comfort and appearance of glasses.

Photocuring 3D printers realize 3D printing by curing photosensitive resins. Its working principle is roughly as follows:

Designing the model: First, a 3D model is created using computer-aided design software such as CAD.

Slicing processing: the 3D model is cut into thin slices, and the shape and contour of each layer are determined by a computer program.

Printing preparation: inject photosensitive resin into the printing tank of the printer, and adjust the position and angle of the printing platform mechanically or manually.

Printing process: The light-curing 3D printer coats the resin on the printing platform through the print head coated with photosensitive resin. Then, a UV light source from the print head shines on the surface of the resin, causing it to cure. The cured resin is piled up sequentially on the printing platform, and the required 3D model is printed layer by layer.

Post-processing: After the printing is completed, the 3D printing model needs to be removed from the printing platform, and at the same time, the excess resin should be cleaned to remove, and light curing and other treatments should be performed to make the printed model stronger and more beautiful.

Generally speaking, the light-curing 3D printer adopts the printing technology of layer-by-layer accumulation, and through the irradiation of precise ultraviolet light source, the resin coated on the printing platform is cured layer by layer, and finally the required 3D model is formed.

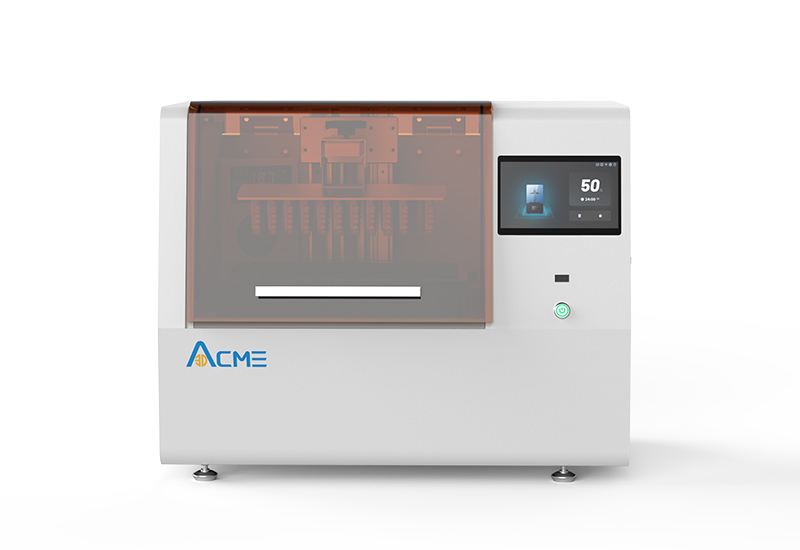

ACME light-curing 3D printer can also be used in the above industries, and has the advantages of high precision, high efficiency, and good stability.

ACME light-curing 3d printer R3 pro has advantages in the following aspects:

+86 19958086067

sales@3dacme.com